Pellet Mill with Rotating Roller Design:

There are two designs of flat die home pellet mills or you can say small home pellet mill . They are home pellet mill with rotating die and home pellet mills with rotating rollers. With these two small home pellet mills, you will know how to make wood pellets. The first type has a stationary roller shaft with a rotating die, as a result when making wood pellets the die is rotating while the rollers is stationary; the working principle of the second design is completely different from the previous one, it has a stationary die with a rotating roller shaft ,so when working the die is stationary but the rollers are rotating.

As to the advantages of home pellet mill with rotating roller design, we generally conclude into two main aspects. On the one hand, the design of rotating roller has much longer service life than the traditional design, it is about 2000 hours; on the other hand, the length of the wood pellets which produced by the design of rotating roller is much longer too, it could be 3cm or more.

1.Application and Performance Characteristic

1.1 Scope of application

Model ZLSP R-Type series home pellet mill, the new type of home pellet mill, is specialized in industrial biomass fuel field, which can be used in the process of sawdust, straw, chaft, bamboo crumbs, peanut shell, bagasse, alfalfa and so on.

1.2. Photos

2. Performance Characteristic:

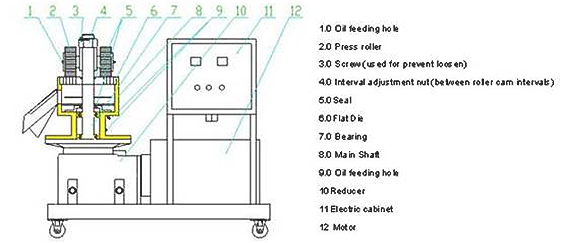

2.1. Structure

2.2. Special Features:

- The gear of gear box uses high quality alloy steel with nitrogencase hardening dispose and grinded accurately and particularly; it has steady transmission ,low noise, big bearing capacity, low rising rate in temperature and long life ,and so on superiorities.

- The main shaft is allocated with heavy load Thrust Bearing which bear strong axial force, and has long use life.

- Use big diameter roller to produce in higher capacity, higher pelletize rate, uniformity and higher strength pellets.

- Making wear-resisting process on the roller and flat die, and both sides of flat can be used to extend the use life.

- All of bearings use sealed structure to prevent entering dust; change the work environment of bearings and extend the use life of bearings.

- The diameter of pellets from 6-12mm, which can be chose by users freely.

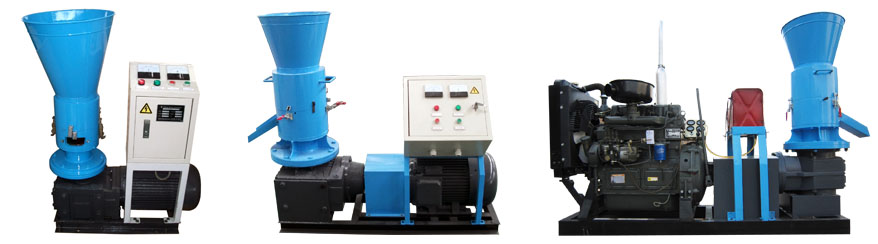

R Type Pellet Press driven by Electric & Diesel Engine

| Driven by | Model | Power | Capacity (kg/h) | Weight (nw/gw) | Packing Size (mm) |

| Electric Motor | ZLSP-R 200B | 7.5kW | 80-120 | 215/245 | 950x450x1050 |

| ZLSP-R 300B | 22 kW | 250-350 | 540/575 | 1350x750x1400 | |

| ZLSP-R 400B | 30 kW | 350-450 | 770/810 | 1400x800x1450 | |

| ZLSP-R 550B | 55 kW | 500-800 | 1770 | 2300x750x1850 | |

| Diesel Engine | ZLSP-R 200A | 15HP | 80-120 | 320/350 | 1460x950x1100 |

| ZLSP-R 300A | 41 HP | 250-350 | 850/890 | 1100x700x2480 | |

| ZLSP-R 400A | 55 HP | 350-450 | 1010/1050 | 1300x800x2600 |

3. Technical Parameter

Model ZLSP30 R-Type pellet mill technical parameter

| Capacity | 250-350kg/h |

| Motor power | 22kw |

| Dimension of package | 1300*600*1400mm |

| Weight | 575kg |

| Diameter of final pellet | 6-12mm |

| Material of flat die & roller | Alloy Steel |

| Life of flat die & roller | min 800hrs |

QA: the OA of motor and gear box is 1 year; the upper body and box of main shaft is five years; others is 1 year besides of wearing parts.

Model ZLSP40 R-Type Pellet Mill technical parameter

| Capacity | 350-450kg/h |

| Motor power | 30kw |

| Dimension of package | 1400*700*1600mm |

| Weight | 810kg |

| Diameter of final pellet | 6-12mm |

| Material of flat die & roller | Alloy Steel |

| Life of flat die & roller | min 800hrs |

QA: the OA of motor and gear box is 1 year; the upper body and box of main shaft is five years; others is 1 year besides of wearing parts.