AGICO offers two types of electric control system in order to improve the production capacity and low energy consumption.

PLC control system

PlC automatic control system is designed to lower energy consumption, improve the productivity, and make sure the maintenance of the biomass pellet plant. The system can control the pellet mill operation automatically according to the working conditions, to a large extent, this can increases the work efficiency and productivity and save energy. Moreover, it can provide runtime history checks, timely maintenance reminders etc.

PLC automatic control system adopts SIEMENS PLC controller, including motherboard, input & output module, software.

MCC for Wood Pellet Machine adopt Touch Panel, Simulation Control Screen or Computer Control Screen and they are optional.

Functions:

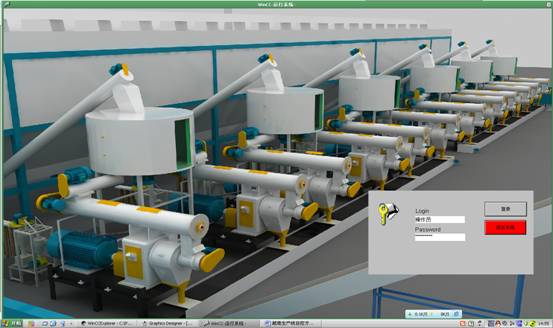

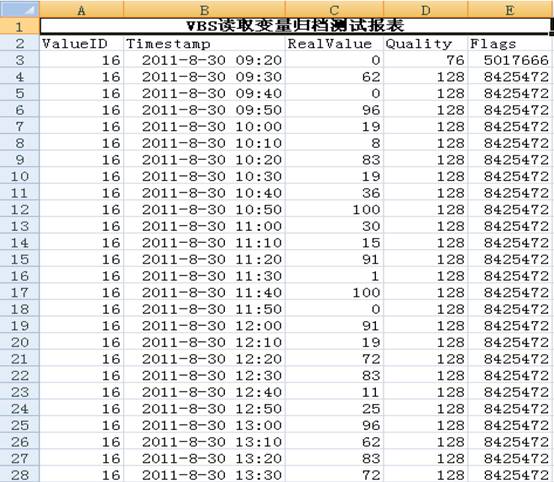

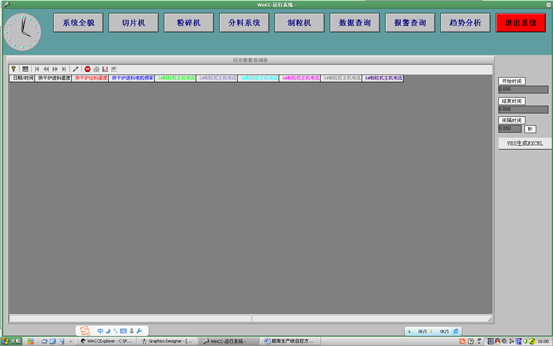

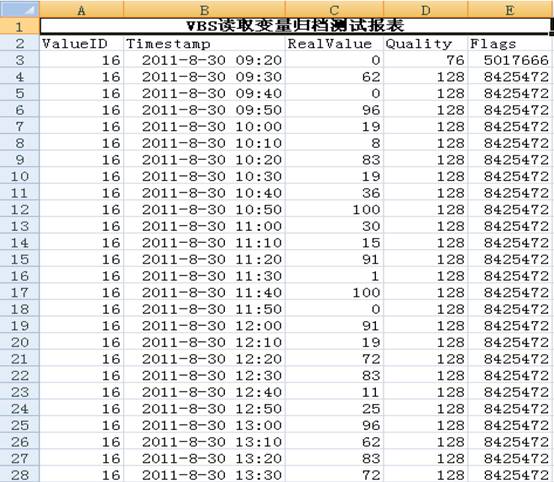

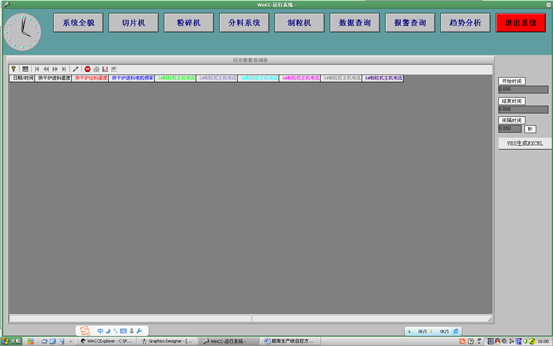

1.Operators with different identities can log in the system. The operator just need choose an identity on the landing interface, as shown in the picture.

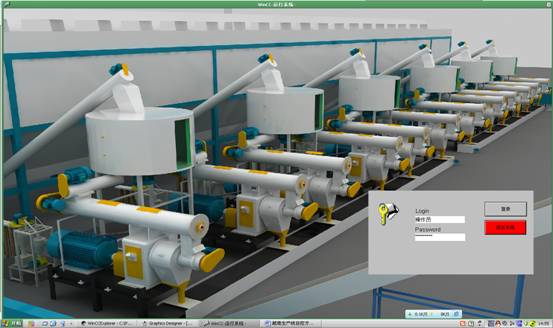

2.After logging in the system, operators can control the entire production process by clicking on the different functional buttons on the interface in order that real time monitoring can come true. Refer to the picture below.

Functions:

1.Operators with different identities can log in the system. The operator just need choose an identity on the landing interface, as shown in the picture.

2.After logging in the system, operators can control the entire production process by clicking on the different functional buttons on the interface in order that real time monitoring can come true. Refer to the picture below.

3.As long as the production line runs normally, operators can realize flexible switch between manual & automatic by click the remote button, they can supervise the whole production process from the feeding of raw materials to the final Pelletization.

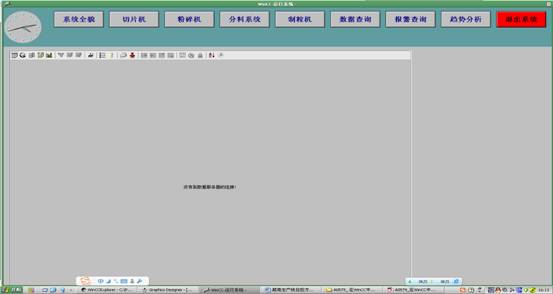

4.Operators can press the “remote hand control” button under some certain circumstance, just like to start or stop of a specific section of or the whole production line. Consult the following picture.

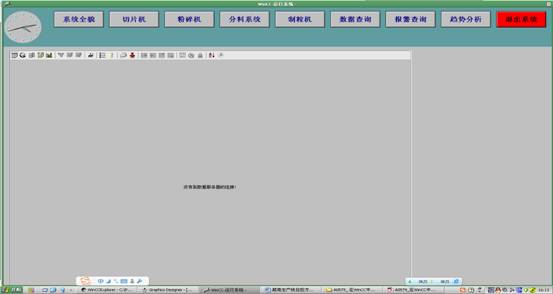

5.If the on-site technicians need data support, operators can click on the “alarm check” button, the system will automatically switch into the alarm recording interface.

6.After clicking on the “trend analysis” button, the trend analysis interface will be presented. Thus operators can refer to the operational parameters in visualized diagrams and it can be observed clearly.

General electrical control system

The working status of the main motor, such as the status of the current, voltage and power consumption of each hour can be displayed by the advanced electrical apparatus elements together with the speed controller.