Biomass Gasification Suppliers/Small Scale Biomass Gasification

Biomass gasification plant for gas supplying or power system is a system which gasifies biomass and purifies the producer gas to produce clean combustible gas for cooking and heating use as well as for power generation, a gas container sized depending on the final use and pipelines as well as the indoor facilities (only in the case of cooking and heating) are necessary for this system.

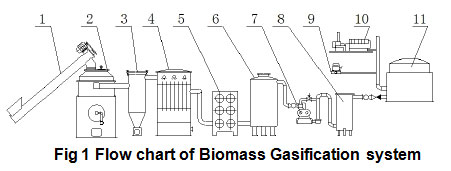

As shown in the following figures, biomass feedstock is first fed into the hopper of gasifier, then the feedstock will be gasified and the crude combustible gas is produced, by the cyclone separators, large particles in the producer gas will be removed, the scrubber will remove the fine particles and tar content in the producer gas, the producer gas then is drawn into the separator where the water droplets in the gas will be removed, with the biomass filter, the produce gas is further purified, a roots blower is used to pump the clean producer gas in the gas tank or gas container, with the underground pipelines, the producer gas can be finally used for every household. After the gas tank or gas container, the gas also can be introduced into IC engine for power generation as well.

1.screwer 2.gasifier 3.cyclone 4.scrubber 5.water separator 6.filter 7.roots blower 8.water seal 9.cooking range 10. IC engine 11. gas tank

Specification (for all available types)

| Capacity | 50-1000Nm3/h |

|---|---|

| Gas supplying capacity | 50-1000 households |

| Power genenration | 15-300kWe |

| Fuel consumption | 25-500kg/h |

| Power consumption | 3-16kW/h |

| Water consumption | 300-400kg/week |

| Heat Value | 4500~5500kJ/m3 |

| Gasification Rate | 70~75% |

| Efficiency for power generation | 18~20% |

| Average life span of the system | 10years |

| Tar and Ash Content in producer gas | 20 mg/Nm3 |

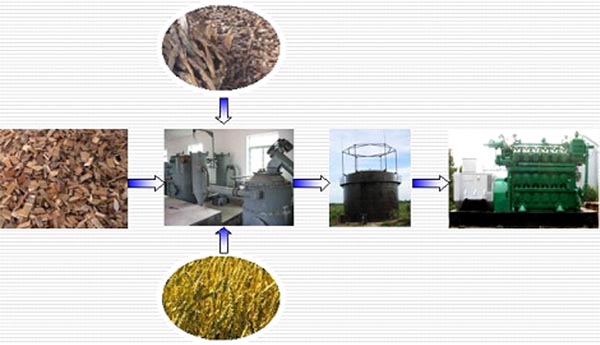

Biomass available for the system

Almost all kinds of agricultural residues such as corn stalk, wheat stalk and etc. as well as the residues of forest industry are all available for the system, except for rice husk and rice straw due to their higher ash content which is around 25%.

Typical Gas Composition

| Fuel Composition | H2% | CO% | CH4% | C2H 2+C 2H4 % | C3H8% | CO2% | N2% |

| Wood piece | 13% | 20% | 4% | 2.6% | 1.58% | 11% | 44% |

| Corn stalk | 12% | 18% | 4.8% | 1.8% | 1.32% | 12% | 45% |