Small Palm Kernel Oil Press

|

MODEL |

CAPACITY(KG/H) |

POWER(KW) |

NET WEIGHT(KG) |

PACKING(MM) |

|

YZS-68 |

40 |

5.5 |

130 |

1050*660*760 |

|

YZS-80 |

80-125 |

5.5 |

330 |

1320*440*695 |

|

YZS-95 |

160-200 |

11 |

420 |

1910*610*765 |

|

YZS-100 |

160-200 |

7.5 |

400 |

1860*550*695 |

|

YZS-120 |

200-300 |

11 |

700 |

2060*610*770 |

|

YZS-130 |

375-500 |

18.5 |

700 |

2320*700*780 |

|

YZS-160 |

550-700 |

18.5 |

920 |

2020*700*780 |

|

YZS-165 |

620-830 |

22-30 |

1600 |

2120*800*980 |

|

MODEL |

CAPACITY(KG/H) |

POWER(KW) |

NET WEIGHT(KG) |

PACKING(MM) |

|

YZL78A |

42-65 |

5.5 |

210 |

1000*550*580 |

|

YZL95A |

150-210 |

7.5-11 |

520 |

1600*700*1350 |

|

YZL105 |

200-300 |

11-15 |

560 |

1825*700*1350 |

|

YZL130 |

420-500 |

18.5 |

820 |

2010*800*1380 |

|

200A-3 |

330-500 |

18.5 |

5000 |

2850*1850*3270 |

Large Palm Kernel Oil Press

| MODEL | CAPACITY(T/D) | POWER(KW) | NET WEIGHT(KG) | PACKING(MM) |

| YZL18 | 6-10 | 37.7 | 3500 | 3176*1850*2600 |

| YZL24 | 20 | 45 | 5000 | 2900*1850*3240 |

| YZL28 | 40-60 | 50+11+4 | 9160 | 3740*1920*3843 |

| YZL32 | 90-120 | 90+11+5.5 | 11000 | 4100*2270*3850 |

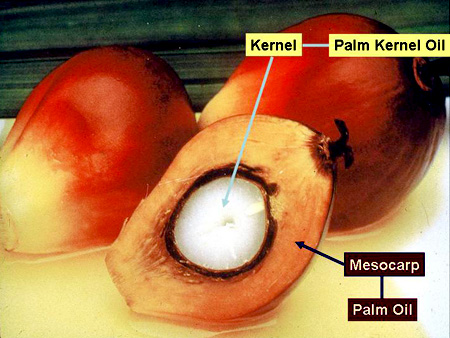

About Palm Kernel Oil

Uses

Splitting of oils and fats by hydrolysis, or under basic conditions saponification, yields fatty acids, with glycerin (glycerol) as a byproduct. The split-off fatty acids are a mixture ranging from C4 to C18, depending on the type of oil/fat.

Resembling coconut oil, palm kernel oil is packed with myristic and lauric fatty acids and therefore suitable for the manufacture of soaps, washing powders and personal care products. Lauric acid is very important in soap making. A good soap must contain at least 15 per cent laurate for quick lathering while soap made for use in sea water is based on virtually 100 per cent laurate.[16]

Derivatives of palmitic acid were used in combination with naphtha during World War II to produce napalm (aluminum naphthenate and aluminum palmitate).[17]

Biodiesel, biomass and biogas

Palm kernel oil, like other vegetable oils, can be used to create biodiesel for internal combustion engines. Biodiesel has been promoted as a renewable energy source to reduce net emissions of carbon dioxide into the atmosphere. Therefore, biodiesel is seen as a way to decrease the impact of the greenhouse effect and as a way of diversifying energy supplies to assist national energy security plans.

Palm is also used to make biodiesel, as either a simply-processed palm kernel oil mixed with petrodiesel, or processed through transesterification to create a palm kernel oil methyl ester blend, which meets the international EN 14214 specification, with glycerin as a byproduct. The actual process used to make biodiesel around the world varies between countries, and the requirements of different export markets. Next-generation biofuel production processes are also being tested in relatively small trial quantities.

Market

According to Hamburg-based Oil World trade journal, in 2008, global production of oils and fats stood at 160 million tonnes. Palm kernel oil and palm oil were jointly the largest contributor, accounting for 48 million tonnes or 30% of the total output. Soybean oil came in second with 37 million tonnes (23%). About 38% of the oils and fats produced in the world were shipped across oceans. Of the 60.3 million tonnes of oils and fats exported around the world, palm oil and palm kernel oil make up close to 60%; Malaysia, with 45% of the market share, dominates the palm oil trade.