Briquette Presses

Our briquette presses have two larger rollers in a fixed position in the frame, the other two smaller rollers are moveable. Briquette equipment has four rollers and do twice pressing in production of briquettes. The briquette is stronger and in higher density, and the surface of briquette machines is smoother.

Suitable material for briquette presses:

color and black metallic mine powder:

Iron scale, iron sludge,Precipitator dust, Iron concentrate, Raw material powder,

Manganese ore fines,Silicomanganese alloy. Etc.

Coal:

Coal powder, coke powder, slime peat, middle coal,lignite etc.

Other material:

Charcoal powder, fireproof material, Desulfurized gypsum,Dolomite etc.

Anyway, briquetting is the only one way to change the powdery material into briquettes which is suitable for transporting, in the meantime, this way also saves engery.

Main Technical Data of Briquetting Press

Main Technical Data of Briquetting Press

|

Model

|

capacity

|

Power(kw) |

Speed of main shaft

|

Type of pressure

|

Material of roller

|

Form of structure

|

|

GCXM-4

|

4TPH

|

7.5-15

|

18r/min

|

Mechanical

|

65Mn

|

Four roller double press

|

|

GCXM-6

|

6TPH

|

11-18.5

|

15r/min

|

Mechanical

|

65Mn

|

Four roller double press

|

|

GCXM-8

|

8TPH

|

15-22

|

15r/min

|

Mechanical & Hydraulic

|

65Mn 9cr2Mn

|

Four roller double press

|

|

GCXM-10

|

10TPH

|

18.5-30

|

13r/min

|

Mechanical & Hydraulic

|

65Mn 9cr2Mn

|

Four roller double press

|

|

GCXM-15

|

15TPH

|

30-45

|

13r/min

|

Mechanical & Hydraulic

|

65Mn 9cr2Mn

|

Four roller double press

|

|

GCXM-20

|

20TPH

|

55-75

|

13r/min

|

Mechanical & Hydraulic

|

65Mn 9cr2Mn

|

Four roller double press

|

|

GCXM-30

|

30TPH

|

75-90

|

10r/min

|

Mechanical & Hydraulic

|

65Mn 9cr2Mn

|

Four roller double press

|

Briquetting technology

Briquetting is the transformation of a powdery or granular product into a larger more convenient size. This is accomplished by compacting the product with a roller press sometimes in the presence of a binder material. The briquettes can be produced with high or low pressure and can undergo mechanical or thermal treatment according to the characteristics of the processed material, the binder used and the desired end product.

Anyway, briquetting is the only one way to change the powdery material into briquettes which is suitable for transporting, in the meantime, this way also saves engery.

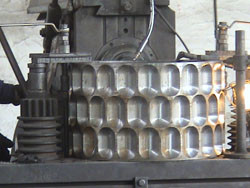

Rollers and Briquettes

Briquetting is the transformation of a powdery or granular product into a larger more convenient size. This is accomplished by compacting the product with a roller press sometimes in the presence of a binder material. The briquettes can be produced with high or low pressure and can undergo mechanical or thermal treatment according to the characteristics of the processed material, the binder used and the desired end product.

Anyway, briquetting is the only one way to change the powdery material into briquettes which is suitable for transporting, in the meantime, this way also saves engery.

Rollers and Briquettes

|

|

|

|

|

|

|

|

|

|

|