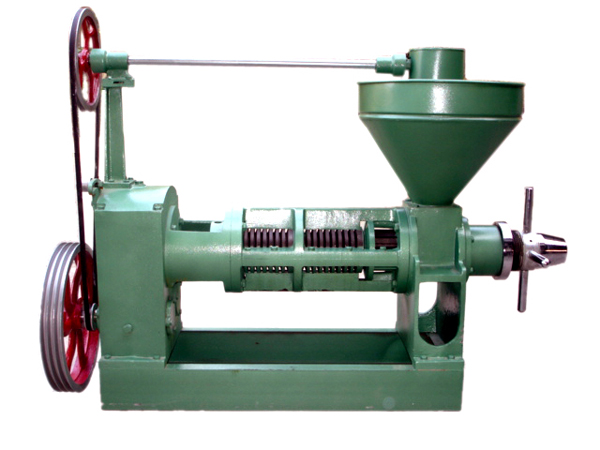

The oil press equipment is currently the main crushing production tool for edible oils such as peanuts and sesame. Therefore, whether it is an oil mill or an edible oil refining processor, special attention must be paid to the maintenance and maintenance of hydraulic oil press equipment. Maintenance and maintenance work must be done well, otherwise it may affect normal production.

The daily protection essentials of the oil press

During the use of the oil press, the cake should be checked frequently. If the cake is not smooth or the cake is stopped, the feeding should be stopped, the feed port should be removed, and the spindle should be slowly removed to clear the blockage.

When the oil press is working, the slag should be removed continuously to prevent the oil circuit from being blocked. The oil slag that is taken over can be returned to the hopper for further pressing.

The oil press shows problems, when the screw shaft is stuck, it should stop immediately, insert the inserting plate, the discharge plate opens, and immediately retract the screw shaft.

Lubricate the parts regularly by lubricating grease and lubricating oil.

The essentials of oil press maintenance

The oil press should check the lubrication situation after every 50 hours of operation. The inside of the gearbox should not be short of oil. The screw shaft should be adjusted to adjust the inner bearing of the screw from the adjustment screw hole.

The oil-removing parts of the oil press should prevent the intrusion of dust and other impurities. Check the oil quality of the gearbox once a year, and find that the oil should be replaced.

Oil press When the pressing amount is reduced and the cake or oil is not normal, the screw shaft should be pulled out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

After the shifting of the oil press is completed, the residual cake in the machine should be removed and the dust and grease on the surface of the machine should be cleaned. The entire oil press can be repaired once in 6 months. All inspections must be dismantled during maintenance, and repairs or replacements are required if damaged.

When the oil press is in the long-term storage after the end of the production season, it should be maintained once, and the snail, the squeeze bar, the cake ring should be removed and washed, and then oiled and placed in a dry place.

In order to reduce the wear and tear of machinery and equipment, it is indispensable to maintain the machine frequently. First of all, it must be maintained from the details, and the gap between the screw shaft and the cake ring should be ensured. In the normal range, if there is debris in the middle, clean it in time. During the use, the bolts and nuts will loosen, and it is necessary to repair them in time. In addition, important parts of the oil press should be coated with lubricating oil to avoid some parts from oxidizing and rusting with water. Finally, we should pay attention to regular inspection. In the off-season, Check the wiring for bites from the mouse, pay attention to the residue inside the machine, and keep the surface of the machine dry.