A pellet mill, we can also call it a pellet press or pellet machine, is a type of machine that we use to make some raw materials(such as saw dust corn cobs, straw, grass, stalks, wheat brain, rice husk and so on)into pellets. It has multiple uses. For example: it can be used for heating, animal feed, animal bedding, pharmacy, chemicals and so on. There are many different types of pellet mills. In order to help you to choose the right product that you need, here I will introduce the types for you.

According to the working principle, there are mainly two types of pellet mills.

Flat die pellet mill

Flat die pellet mill is usually used to make pellets on a small or medium scale. When it works, we can put the raw materials on the surface top of the die and through the extrusion between die and rollers, the materials through the holes in the die, then pellets can fall from the bottom of the die. There are many advantages of flat die pellet mill. Firstly, it is easy to maintain and clean. Secondly, they require small space and very light, which can be used in small farm and home, but they are not suitable for big factories. Thirdly, it is easy to change new die and rollers, this can save time to produce more pellets.

Generally there are two different designs of flat die pellet mill.. One is with a rotating die and the other is with a rotating roller.

Flat die pellet mill with a rotating die

Flat die pellet mill with a rotating die has a stationary roller with a rotating die. During the pellets making process, the die is rotating and the rollers are fixed. This can make animal feed pellet better than wood pelletvery good,so it is usually used as feed pellet mill.

Flat die pellet mill with a rotating roller

Flat die pellet mill with a rotating roller is different from the previous one. It has a stationary die with a rotating roller, when it is working the die is fixed but the roller is rotating.this is best to make wood sawdust pellets or poultry,so it is used as sawdust pellet mill.

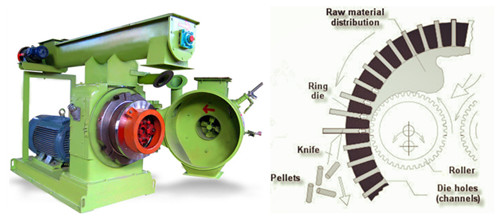

Ring die pellet mill

Ring die pellet mill is suitable for medium or large scale production. It can make large amounts of production and you needn’t worry about the wear. When it works, raw materials are fed into the inside of the die and the rollers press materials through the die holes, Two cutters are used to cut the pellets free from the outside of the die. Compared with flat die pellet mill, ring die pellet mill has large capacity, long service life and low energy consumption. The products are more solid and smooth, moreover, it has bigger commercial value, so if you have a big plant and you want to earn much money, please consider it.

According to the different products, we have some types of pellet mills as following.flollows:

Wood pellet mill

It is a machine that we can use it to convert waste biomass materials (such as wood, corn stalk, straw stalk, sawdust, wood meal and so on) into wood pellets. Log, wood shavings, cutoff, sawdust, The wood pellets can be burned as green fuel in a pellet stove, boiler, biomass power plants etc. It has the advantages of low consumption, low price and high capacity. Generally it is the best choice for small farm family.

Feed pellet mill

The products of this mill is usually used to feed animals, such as chicken, pig, duck, sheep, cattle, cow, etc.. The source of raw materials is very extensive. We can use corn, rice beans, grass meal, straw meal, rice husk, rice beans, and so on. It can be used not only in small, medium or large poultry farm but also at home. The mill has a large capacity. The pellets are very smooth and suitable for animals to eat.

Plastic pellet mill

This is a new-style mill. As the developing of technology, we can change many waste materials into useful things. As we all know, plastic refuse bags are very difficult to change, moreover, they cannot be recycling efficiently. But now we have plastic pellet mill, we can process the raw materials into pellets. The pellets can be used in many fields, e.g.:clothing, construction, agriculture, chemical, machinery industry, electrical equipment industry and so on.

Straw pellet mill

This mill makes straw, sunflower husks, rice husks, coffee husks, bagasse, etc. into small pellets, the raw materials are easy to get, they are very cheap, so the price is low and it can benefit our environment. The products can be used for animals’ bedding, heating etc. the pellets are very soft, so it is comfortable for animals to use. The features of straw pellet mill are high cost performance and high production capacity.

Metal pellet mill

This mill makes waste metal materials into pellets. The materials mainly refer to iron ore. When it works, we must add some additional materials to the iron ore to meet the requirements of the final pellets. And we also need a thermal treatment; this can bake the soft raw pellet to hard spheres. Usually the pellets are used in mechanical industry and steel manufacture.

So now you know that there are different types of pellet mills, if you want to buy pellet mill, please choose one that can meet your requirements.