| 2. The whole line to process

the sunflower seed/pumpkin seed/hemp seed/pine nut seed

The plant is appropriative machine designed to hu ll,

remove shells, separate and re-separate for many kinds

of oil seeds. ll,

remove shells, separate and re-separate for many kinds

of oil seeds.

The distinguished characteristic of the equipment

is that there is no need to grade the raw materials

to more grades, only the AA grade need to be graded

to 2 grades and processed separately. Furthermore,

there is no need to separate the kernels from seeds

by sieves any more, but by the positive-pressure separator.

Therefore, the process has been simplified and the

automatization degree and efficiency have been improved

greatly.

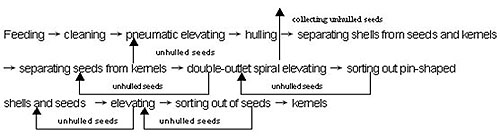

The flow chart

The equipment consists of 1. Feed-in hopper, 2.vibrating

scatter, 3.combined spiral elevator, main part of

machinery (4.huller, 5.shells collector, 6.positive-pressure

separator which separates the seeds from the kernels,

7.cyclone, and 8.spiral discharger), 9.double-outlet

spiral elevator, 10.positive- pressure separator and

electric control cabinet.

Technical Parameters

Power: 13.97Kw(380V)

Processing capacity: 0.8 -1 t/h (kernel)

Rate of whole kernels: 90% min. (Broken

kernel is that less than 1/2 of whole

kernel)

Rate of seeds in the kernels: 2% max.

Rate of seeds and kernels in the shells:

0.3% max.

Occupied area: 18m×2.8m

Height: 3.2m

Weight: 7t

Operator: 2 person

|

|

|

|

|

|